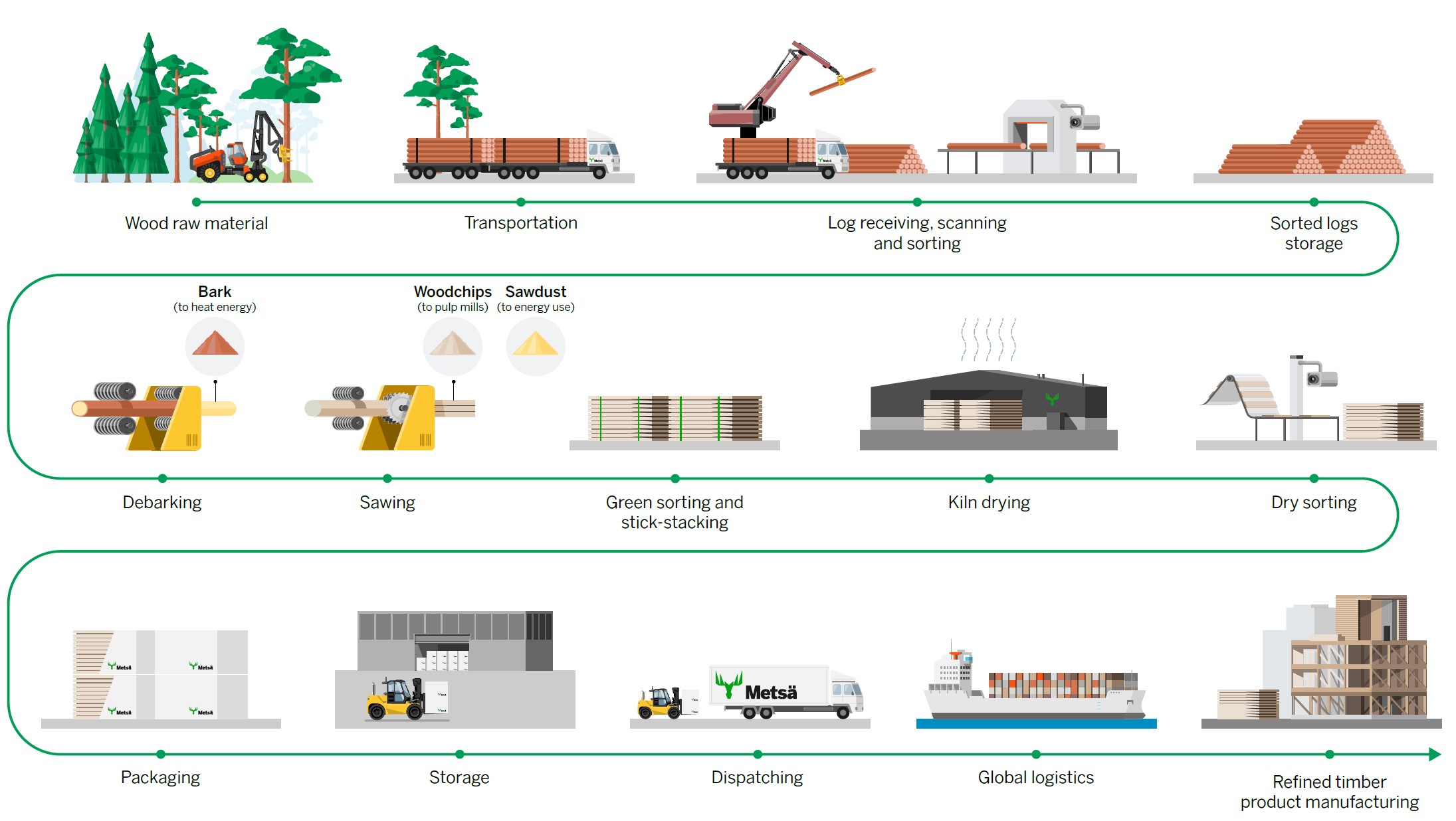

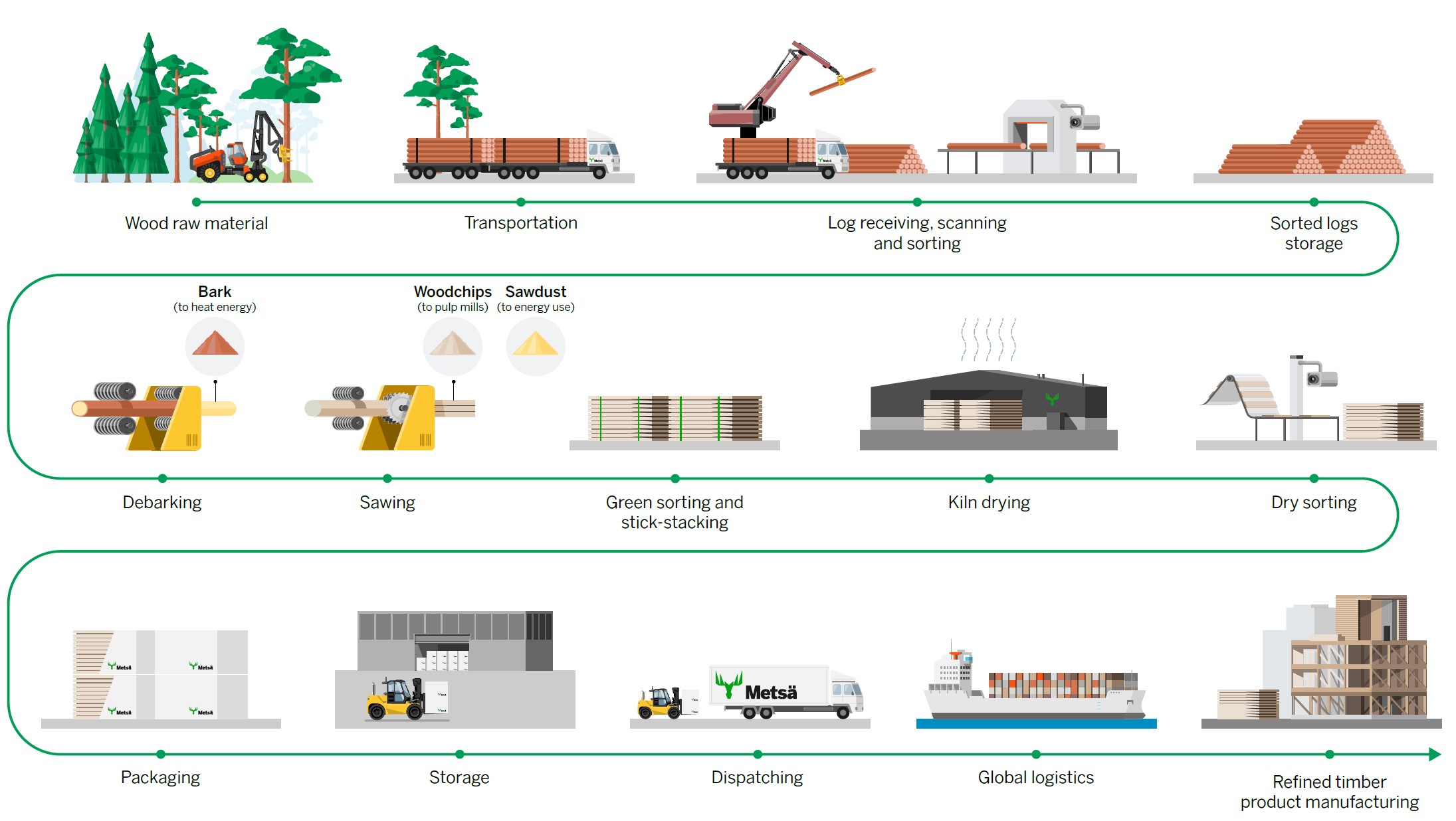

Read more about how we convert renewable wood raw material into sawn timber:

Sawn timber is made of logs, which are the most valuable part of trees. An efficient and meticulous supervision of wood supply forms the basis for our ability to provide our customers with the high-quality products they have ordered, promptly on schedule. We engage in close cooperation with Metsä Group’s wood supply, which provides us with all the log wood we use.

In the forest, trees are cut into logs of the size ordered and transported to the sawmill.

At the sawmill, logs are measured, X-rayed and debarked to ensure that each individual log can be sawed optimally. This allows us to use our wood raw material as efficiently as possible. We use every bit of the tree: the bark, woodchips and sawdust serve as raw material for other bioproducts and bioenergy. Cutting-edge technological solutions such as 3D and log X-ray equipment enhance the process, and allow us to satisfy our customers’ wishes even better.

The boards and planks resulting from the sawing process are dried, sorted and packaged for delivery to customers. We identify the kinds of applications for which the high-quality northern raw material of each of our production units is best suited. This enables us to make efficient use of the properties of wood and create added value for our customers.

The entire process from the forest to the sawmill, and from there to the customer, is highly automated, yet each stage calls for professionals to oversee the process.

Wood products for the woodworking industry, housing construction, furniture and other long-term use can sequester carbon dioxide for up to hundreds of years.

Sawn timber production process