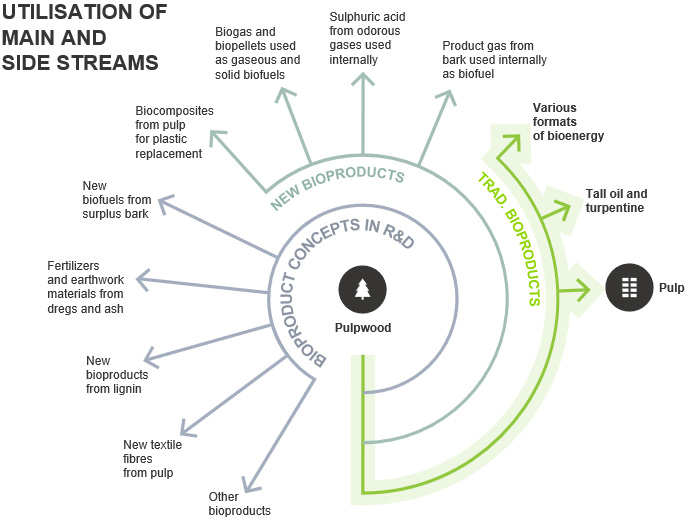

Metsä Fibre’s way of renewing its pulp mills is based on the sustainable bioproduct concept, the core of which is the resource-smart use of the wood raw material and side streams of production. In the bioproduct mill concept, the renewable wood raw material and production side streams will be used in full as pulp and other bioproducts, which can replace fossil-based materials and fossil fuels.

Sustainable bioproducts are created by new-age innovators

The bioproduct mill concept allows for the future expansion of the product range with new bioproducts of an increasingly high added value. The innovations of the future will be created, to an increasing degree, through cooperation. Metsä Fibre actively explores new product paths with its partners, which include for example universities, research institutions, companies and potential customers. In addition, Metsä Fibre has internal channels through which its own personnel have the chance to share their own development ideas and process the ideas of others further, with a low threshold. Alongside product development, the efficient operation of production units also requires long-term partnerships, and Metsä Fibre engages in multi-sectoral cooperation with its strategic business partners and equipment suppliers, among others.

From replacing plastics to creating wood-based textile fibres

The bioproduct mill at Äänekoski, started up in August 2017, is one concrete example of the large-scale practical implementation of the bioproduct concept. Besides pulp, tall oil, turpentine and bioenergy, the mill produces new bioproducts such as product gas, sulphuric acid as well as biogas and biopellets. The bioproduct mill does not use any fossil fuels at all, and the mill’s equipment solutions are world-class in terms of their environmental, material and energy efficiency. With the new mill, the network of companies producing bioproducts in the area is expanding even further. The joint venture of Metsä Group and Itochu is building an industrial demo plant which produces a new kind of wood-based textile fibre next to the bioproduct mill. The demo plant’s production is set begin at the end of 2019.

Another concrete example of both bioproducts based on pulp fibre and partnerships is Aqvacomp’s biocomposite plant, which operates in the mill area of Metsä Fibre’s Rauma pulp mill. The plant converts pulp into biocomposites, which can replace plastic in the electronics and car industries, among others. Metsä Fibre’s pulp mill in Joutseno produces product gas out of bark to be used as a fossil-free fuel in the mill’s own processes.

The new knowledge and know-how gathered from the modern solutions of the Äänekoski bioproduct mill are also used actively at Metsä Fibre’s other production units and when planning new investments. Metsä Fibre has started a prefeasibility study on the modernisation of the Kemi pulp mill. One alternative consists of a new, bigger bioproduct mill, which would enable the expansion of the range of sustainable bioproducts and the development of a business ecosystem in the same fashion as in Äänekoski. The prefeasibility study will be completed in summer 2019.