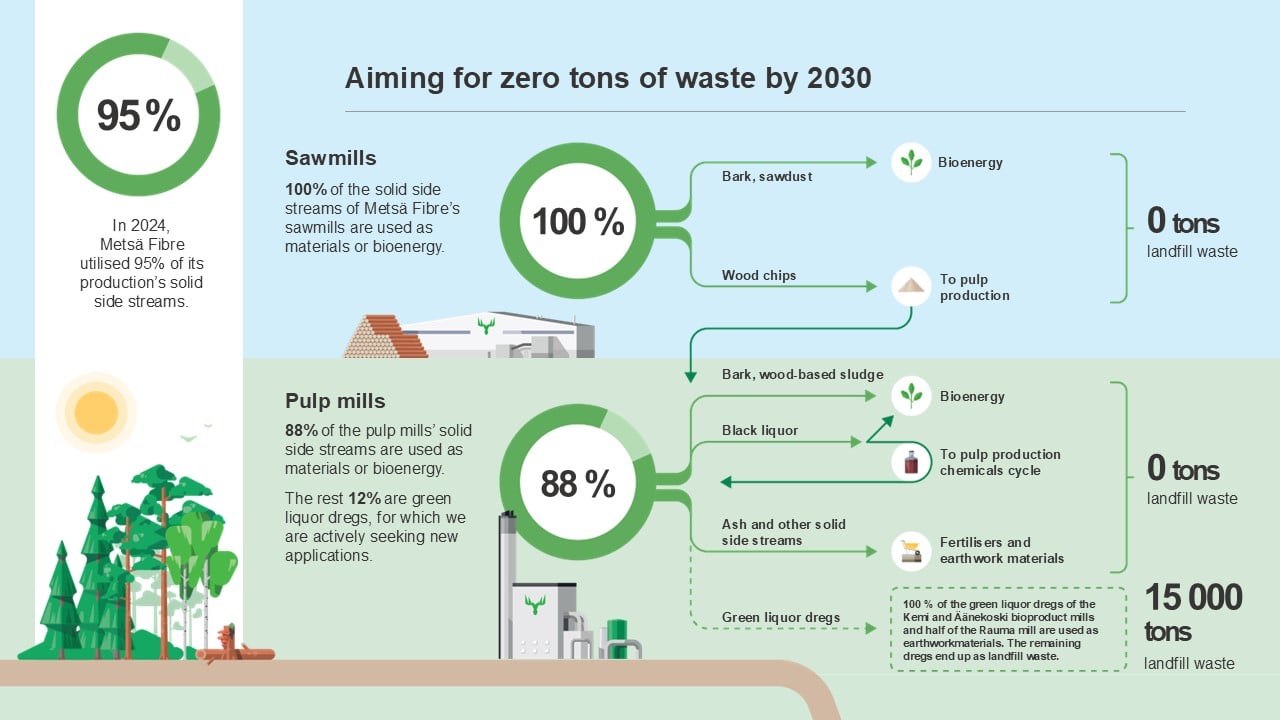

Already, an extremely large portion of production side streams can be put to use as various by-products and energy. In 2024, Metsä Fibre utilized 95% of the solid side streams from production, meaning a relatively small portion ended up in landfills. Our goal is to utilise 100% of production side streams by 2030, resulting in no landfill waste from our production.

Utilising side streams

Wood-based waste and by-product fractions, sludges, ashes, and lime fractions are used in construction and landscaping, fertilizers, chemical industry applications and energy production. The largest process waste fractions are green liquor dregs from pulp production and ash unsuitable for fertilizer use from energy production.

Green liquor dregs are being used on earthworks sites to replace virgin raw materials such as crushed rock and gravel in field structures to save natural resources. Another potential use for green liquor dregs is in geopolymers used to replace materials like concrete. Our partner companies utilise green liquor dregs from the Äänekoski and Kemi bioproduct mills in construction, significantly reducing the amount going to landfills.

We are actively seeking other purposes for green liquor dregs by conducting our own research and pilot projects and participating in universities’ jointly funded research projects.

Future development projects

Future development projects

A strategic R&D programme for converting side streams for use in the circular economy is underway at Metsä Group. We are researching and developing, both independently and with partners, various new purposes for sludge, ashes, lignin, sawdust, bark and many other forest industry side streams. We are also exploring opportunities for carbon recovery and upgrading.

To advance the industrial refinement of lignin, Metsä Group is building a pilot plant for lignin processing at the Äänekoski bioproduct mill in 2024-2025, in collaboration with technology company ANDRITZ. Metsä Fibre and ANDRITZ are developing a new lignin product manufacturing process, its integration into the bioproduct mill, and the product properties required for different end uses. The pilot plant project also includes the chemical company Dow, which is developing bio-based superplasticizers for concrete and gypsum applications using the lignin product manufactured at the pilot plant. In 2025, Veolia's methanol refinery plant will also start operations at the Äänekoski bioproduct mill.