Efficient control and response

Among the materials Metsä Fibre’s production units use as energy are bark, black liquor produced in pulp production and sawdust from sawn timber production.

By utilising the side streams generated in the process as extensively as possible, we improve the resource, energy and environmental efficiency of our production facilities. Efficient control and mitigation of emissions is the cornerstone of managing the environmental impacts of production.

Most of our air emissions originate from the pulp mills’ and power plants’ combustion process. Primary emissions to air are carbon dioxide (CO2), sulphur dioxide (SO2), nitrogen oxides (NOX) and particles from pulp production and power plants. In addition, small amounts of total reduced sulphur (TRS) are emitted from pulp mills.

All our production units have a valid environmental permit. We use the best available techniques in production and continuously monitor that our production units operate in compliance with the environmental permits issued to them. Any deviations and related corrective actions are immediately reported to the authorities and we always take corrective action to resolve the situation.

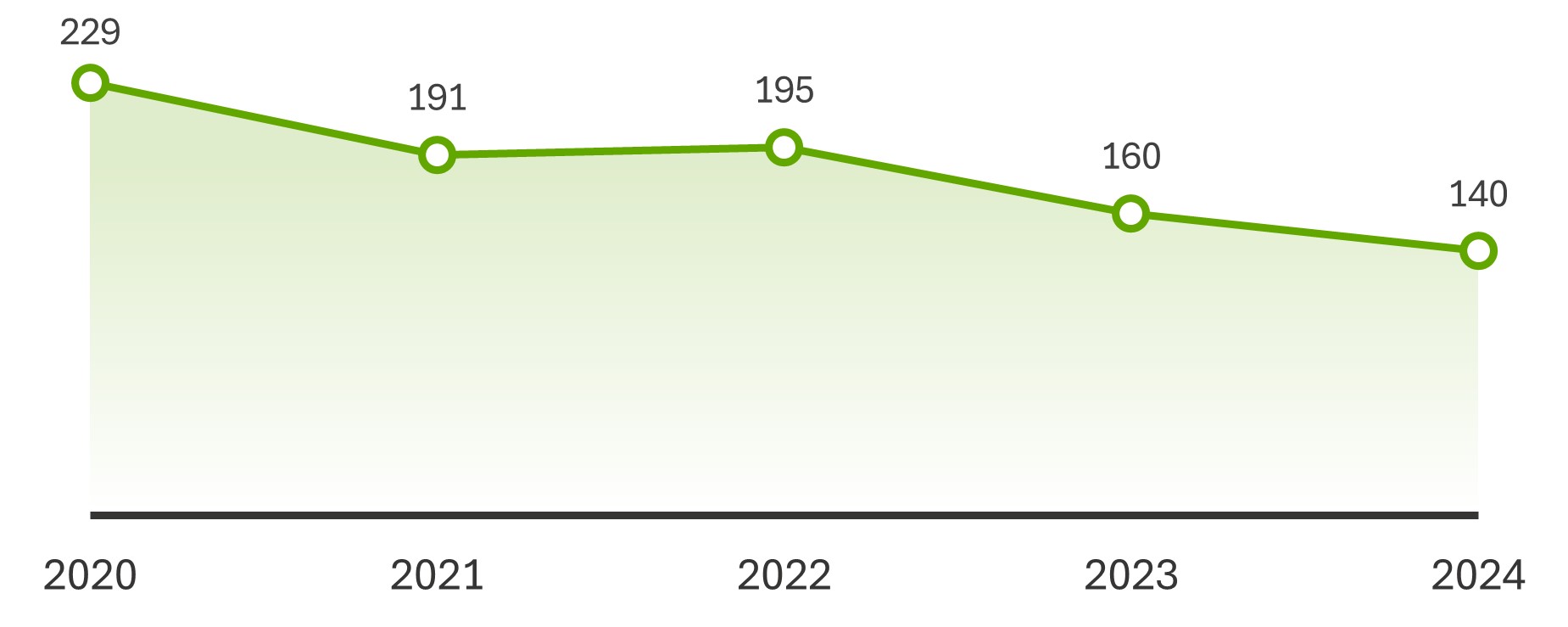

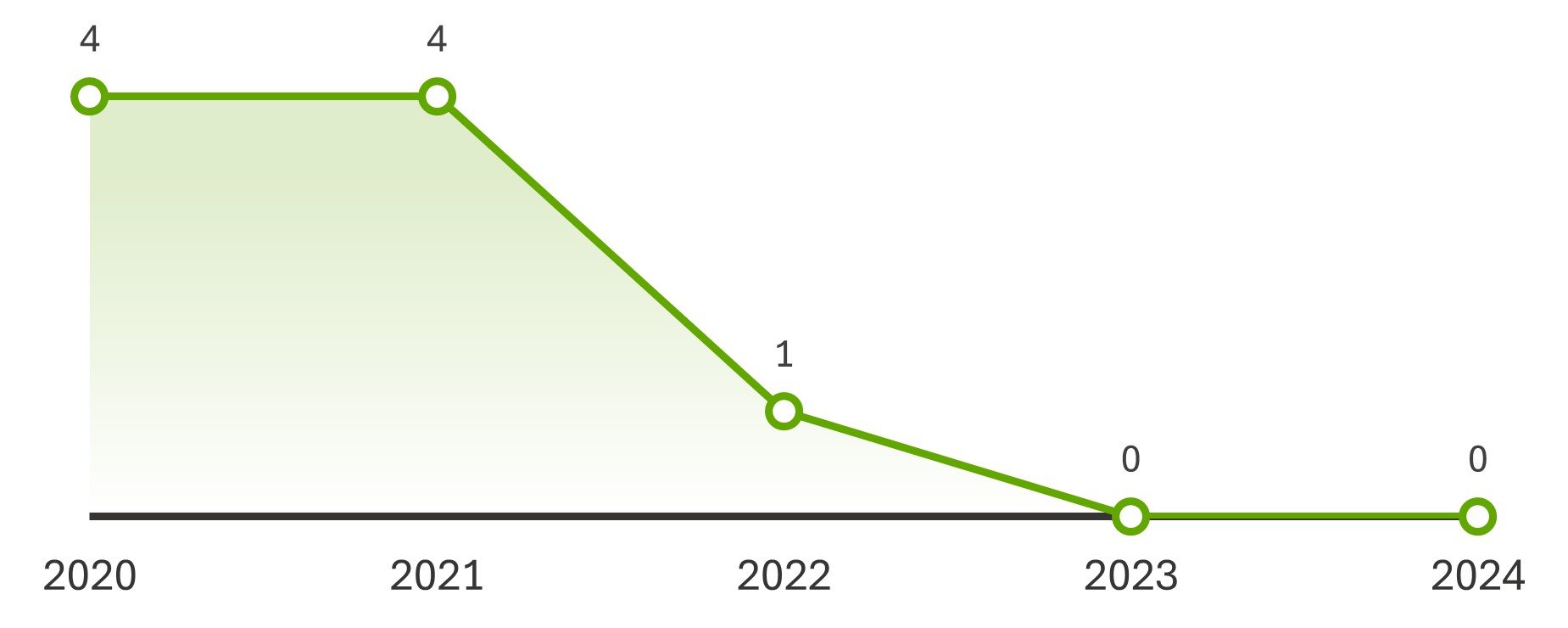

CO2 from fossil sources, tn

| Five year trend 2020–2024, Metsä Fibre total |

| Scope 1 |

|

| Scope 2 |

|

Improving energy efficiency

Our main means of combating climate change are to increase the share of bioenergy and improve energy efficiency. Our objective is that our mills are fossil free by 2030.

The single largest measure reducing fossil emissions and improving energy efficiency was the start-up of production at the Kemi bioproduct mill. As the mill uses zero fossil fuels, fossil-based CO2 emissions will decrease by approximately 68,000 tonnes compared to those of the former mill (2022 emissions from the old Kemi pulp mill).

Proven lower emissions

The life-cycle analysis published in 2023 by the Fraunhofer Institute for Microstructure of Materials and Systems demonstrated that the Äänekoski bioproduct mill’s fossil-based carbon dioxide emissions per tonne produced were approximately 30% lower than those of European pulp mills running Elemental Chlorine Free (ECF) production processes, and 45% lower than those of average Total Chlorine Free (TCF) production.