Pulp production wastewater discharges

In general, our wastewater discharges primarily consist of nutrients (phosphorus and nitrogen), organic substances measured as chemical and biological oxygen demand, as well as suspended solids. The wastewaters of pulp production also contain organic chlorine compounds, sodium and sulphates. The sawmills’ production processes generate nominal volumes of wastewater, which is treated in municipal wastewater treatment plants.

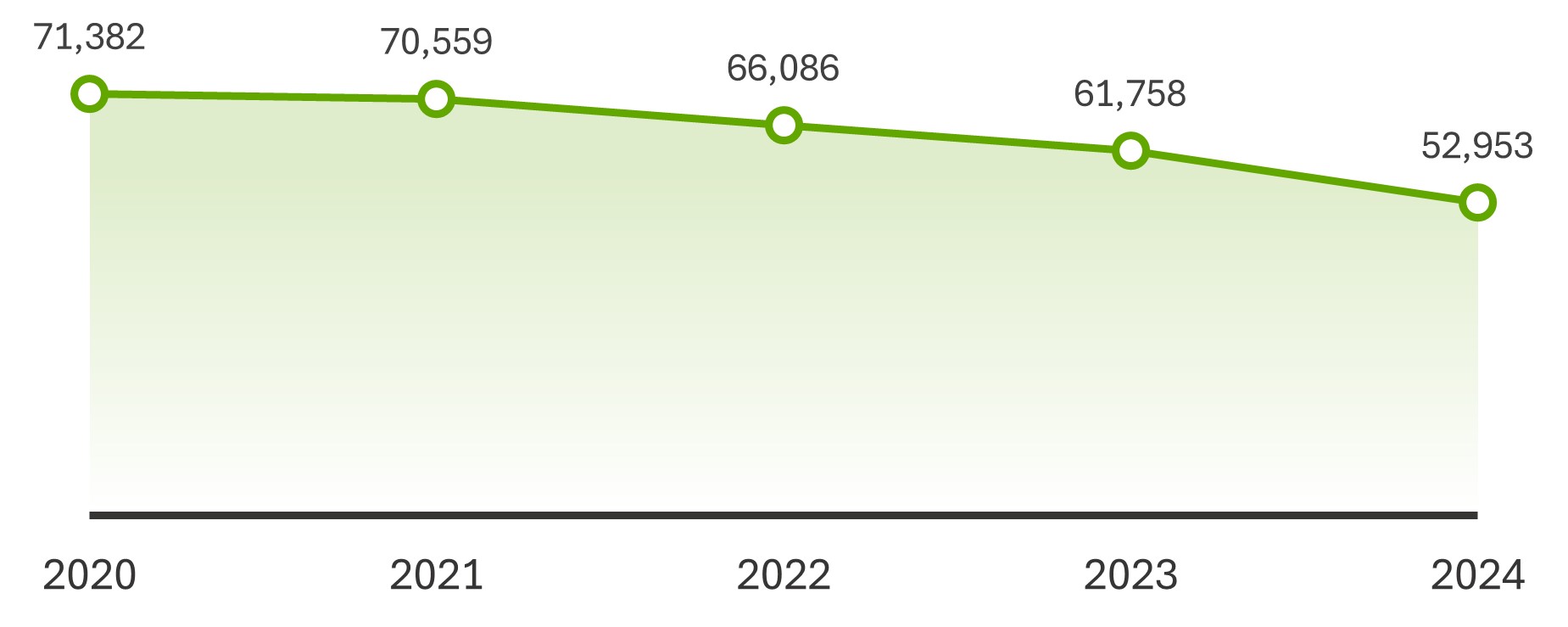

Process water volume, 1,000 m3

| 5 year trend 2020–2024, Metsä Fibre total |

|

Our efforts to reduce water use

Although water is needed for pulp production, the Finnish forest industry is a modest user of water: the industry uses only 0.2% of the available water resources in Finland. The process water is cleaned thoroughly before returned back into the rivers, lakes or sea.

Emissions to water are reduced through reduced water use, more efficient processes and efficient abatement technology.

We are continuously looking for new ways to improve efficiency. An example of this is the Kemi bioproduct mill’s closed cooling water circulation which reduces the thermal load on the water body and the need for water intake. The cooling water is not discharged directly into the water body, but the cooling towers minimise the heat load to the sea.

Optimised water consumption

We only use surface water in our operations. All the process water we discharge is thoroughly purified before being returned to nature. We constantly strive to optimise water use in our processes and increase the efficiency of process water recycling to reduce our use of raw water. This helps us to minimise the amount of water that needs to be heated and reduce wastewater volumes, saving energy and reducing the climate impact of our production.

As our mills are located in water-rich areas in Finland, no water is taken from areas that are classed as being under high or extremely high water stress according to the World Resource Institute’s Aqueduct Water Risk Atlas. Our activities do not impair the availability of water to other parties, such as residents or agriculture.