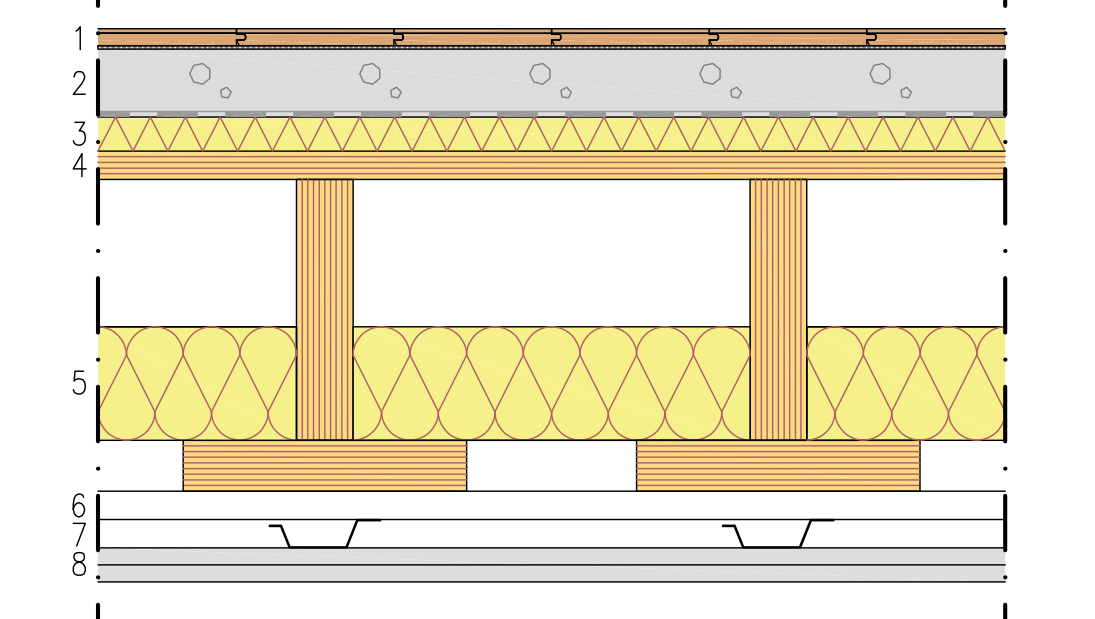

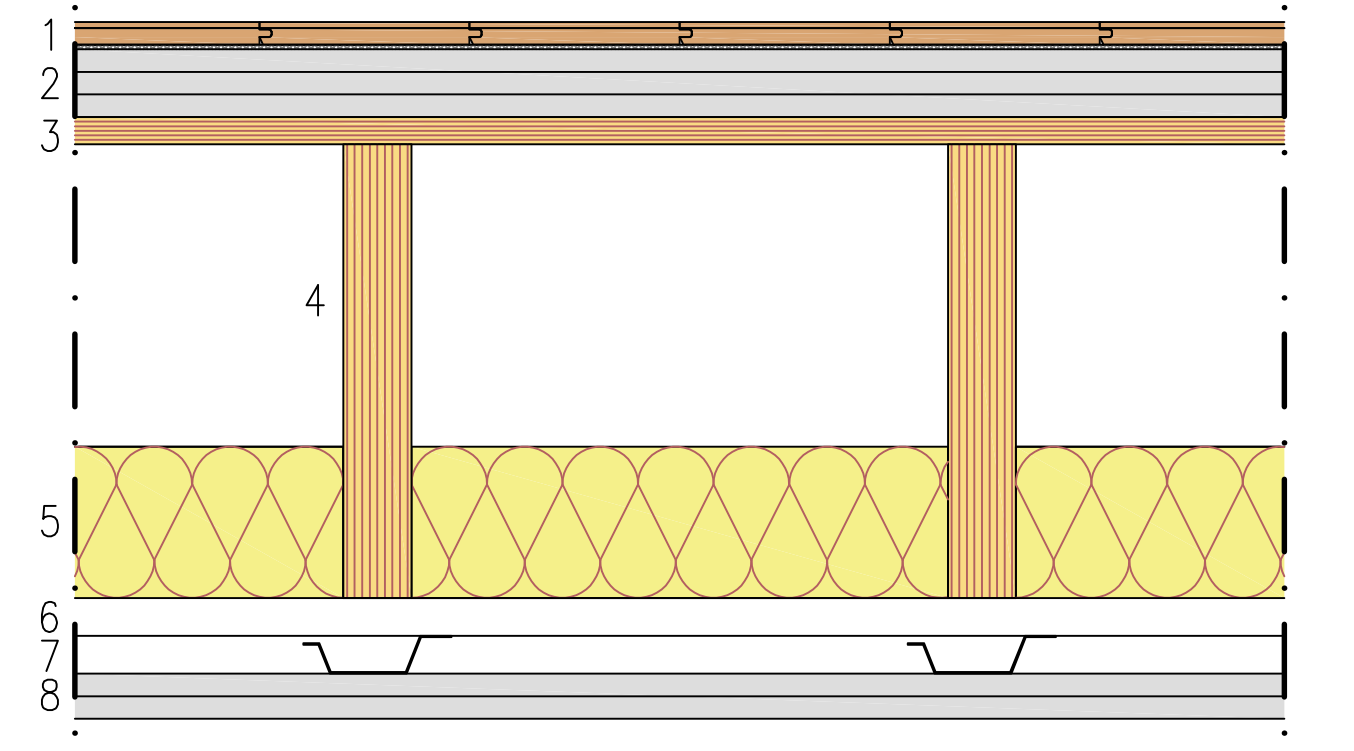

The rib element can be manufactured in two different ways: The ribs are either located on the top or under the element. The prefabrication depth is very variable: for example, the element can be insulated or filled with gravel for sound protection already in the factory. If this is made, it minimizes the total floor height compared to massive timber solutions.

Another benefit is that ventilation, electrical and other installations - with openings of up to 70% of the rib height - can be installed in the element. The design is also highly customisable: the elements can be left visible or covered with plasterboard, for example. In the elements, Kerto LVL S–beam is used as a rib in the element; Kerto LVL Q-panel is used as upper and / or lower panelling. The element manufacturer glue these together in the factory using screw or nail press gluing , thus bringing more added value to your company. With the required glue approval, companies are also strategically positioning themselves for the future. For more information, you can fill in our contact form and we will get back to you.