Standardised prefabricated elements turn construction into industrial business. Same factory manufactured element designs can be reused in different projects. However, with mass-customisation the standardised elements can be combined into unique buildings. At the factory the controlled conditions ensure the high-quality production, and there are no delays due to weather. The installation of the prefabricated elements at the construction site is quick and the overall schedules can be reduced.

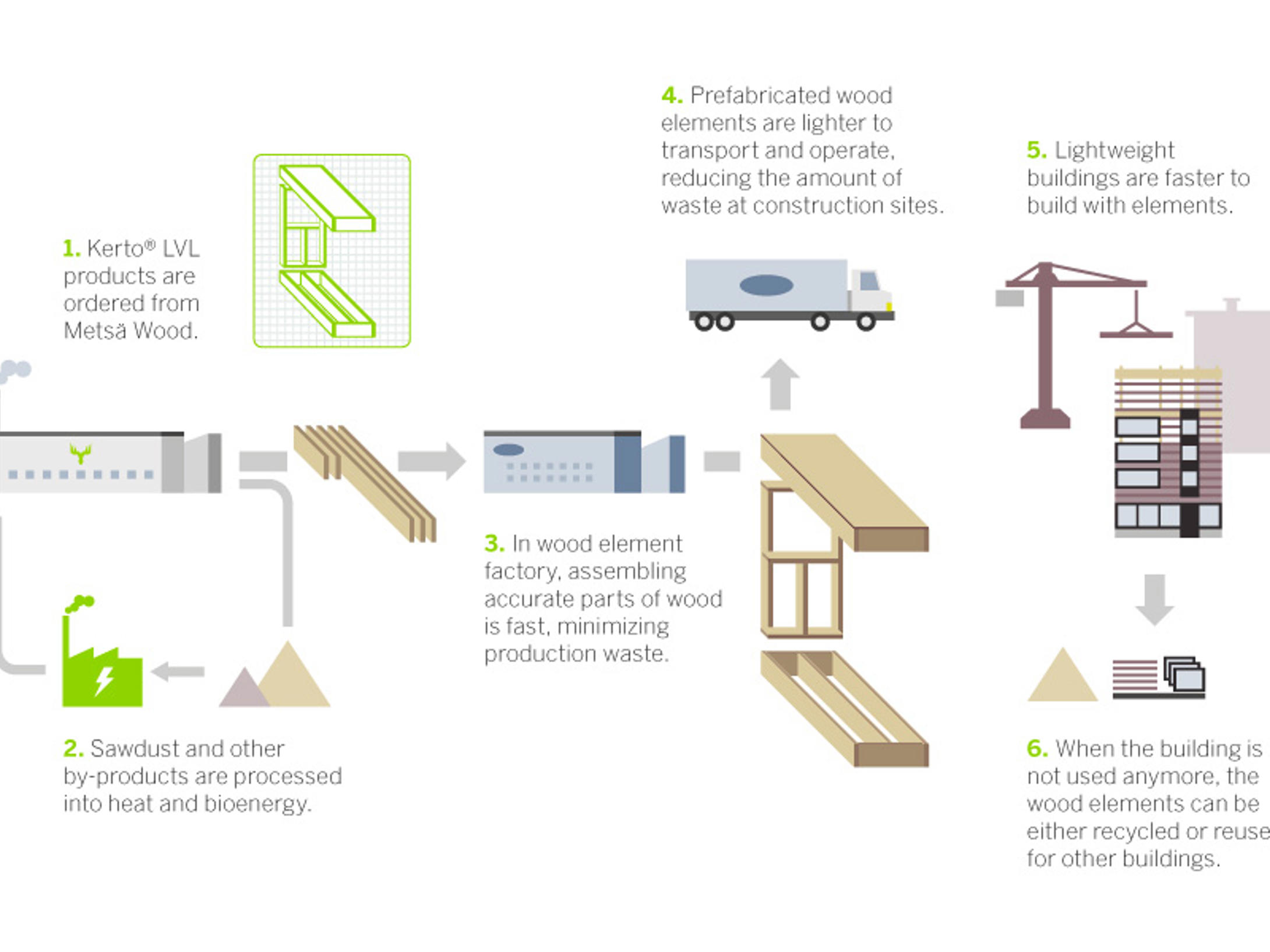

Modular wood construction provides a more efficient and more sustainable option for construction industry. Kerto LVL (laminated veneer lumber) products have many benefits for element manufacturers as they make construction fast, light and green:

- Fast means that wood elements are fast to install. The workability is great, because the wooden elements and modules are easy to fasten, nail and drill.

- Light means that LVL-based elements are light to transport and easy to lift. This means smaller fuel costs, smaller cranes and less traffic on the construction site.

- Green means that using Kerto LVL makes construction more sustainable. Wood is the only renewable major construction material. The wood products used in a building store carbon during their whole life-cycle. Kerto LVL is also a very resource efficient material compared to other engineered wood products.

Growing the modular wood construction through partnerships

Wood construction is becoming increasingly popular worldwide. Wood products have become more competitive in residential construction in particular, due to the advanced degree of modularity and prefabricated elements. Metsä Wood has been making long-term efforts to find permanent partners for industrial wood construction. The aim is to develop an ecosystem based on Metsä Wood’s Kerto LVL products.

Read more about the offsite partnerships.