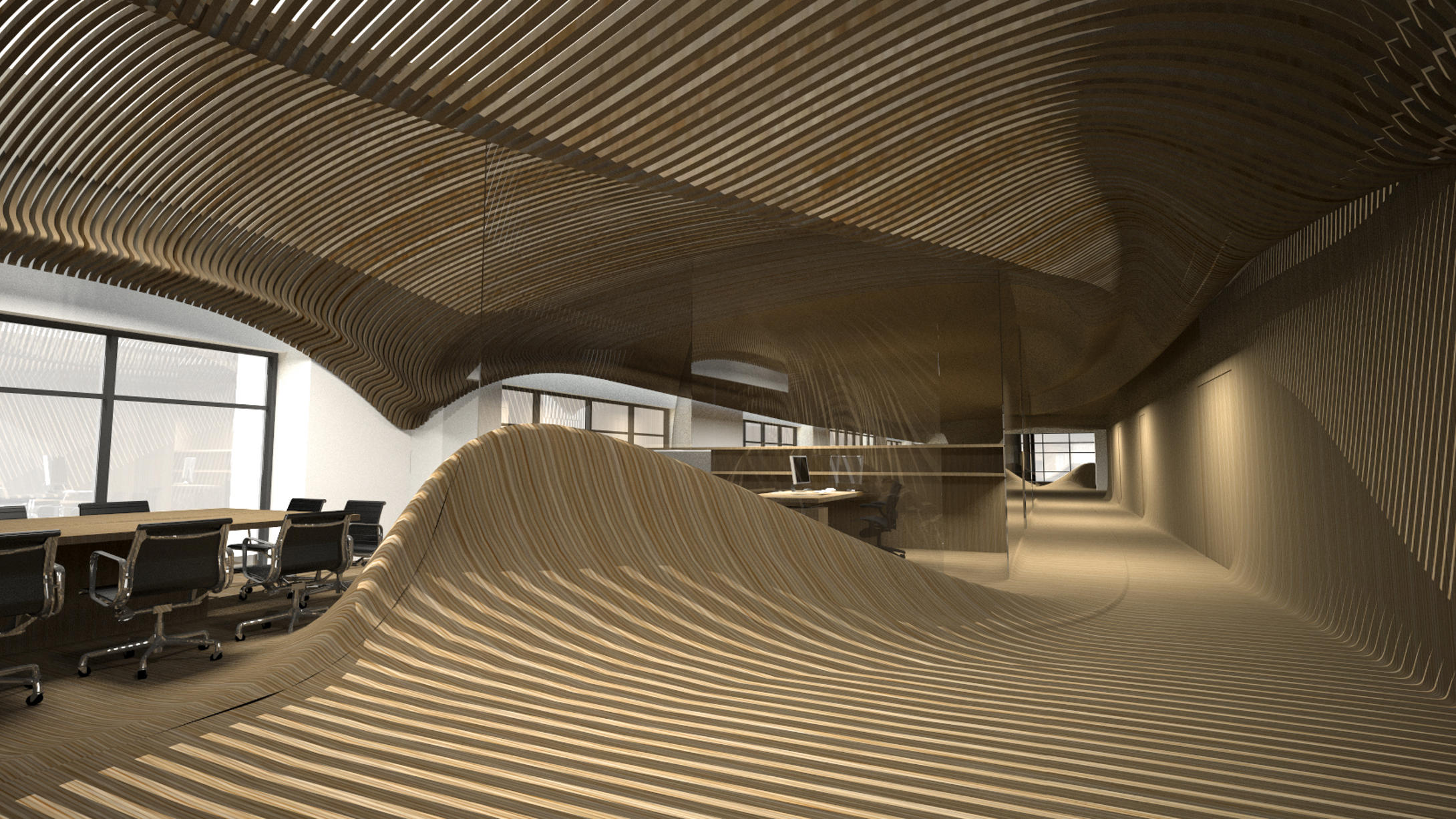

Designing and constructing the wooden interior for the One Main renovation project in Boston, USA is a showcase for an untypical use of Kerto® LVL (laminated veneer lumber). The wavy wooden surfaces that comprise the interior are built entirely from cross-bonded Kerto® LVL panels that are usually used in structural members.

The project’s principal architect, Mark Goulthorpe from dECOi Architects, a professor at nearby MIT, offered a proposal with a greatly streamlined building methodology, where the usual multi-trade, multi-component legacy of late-industrial production was surpassed in a unitary CAD-CAM logic.

Kerto® LVL for wooden interiors

Metsä Wood’s cross-bonded Kerto LVL Q-panel is typically used in structural elements. However, the One Main office in Boston is an excellent example of a completely different way to use the product.