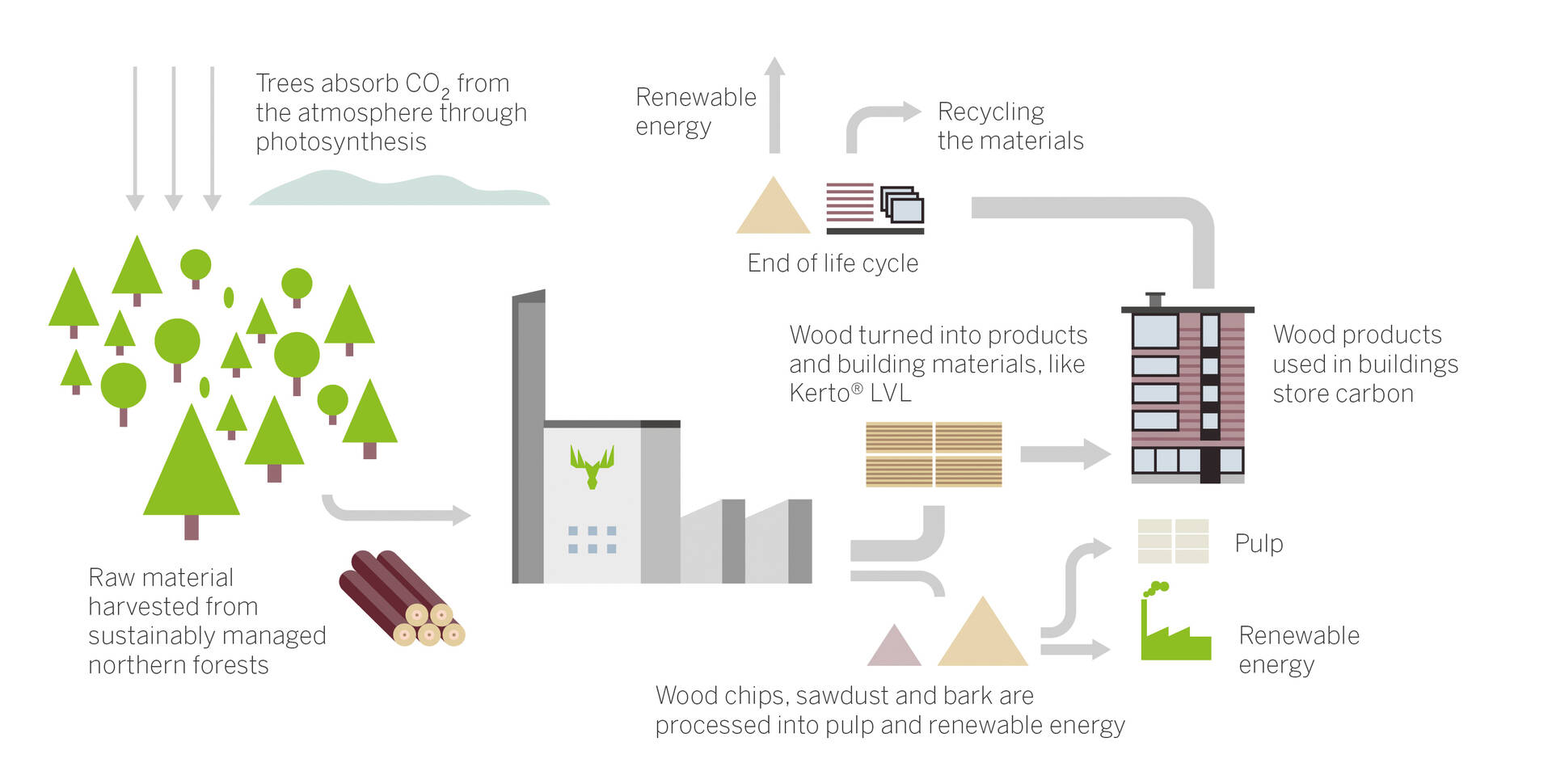

Circular economy starts from the design

The strength of Kerto LVL allows designs that minimise the amount of material used for construction, while its durability allows buildings to be long-lasting, keeping the materials in use and storing carbon. Circularity comes into play at the end of the building's life, when the wooden elements can be reused elsewhere or recycled into new building products. Even the entire building can be relocated and repurposed.

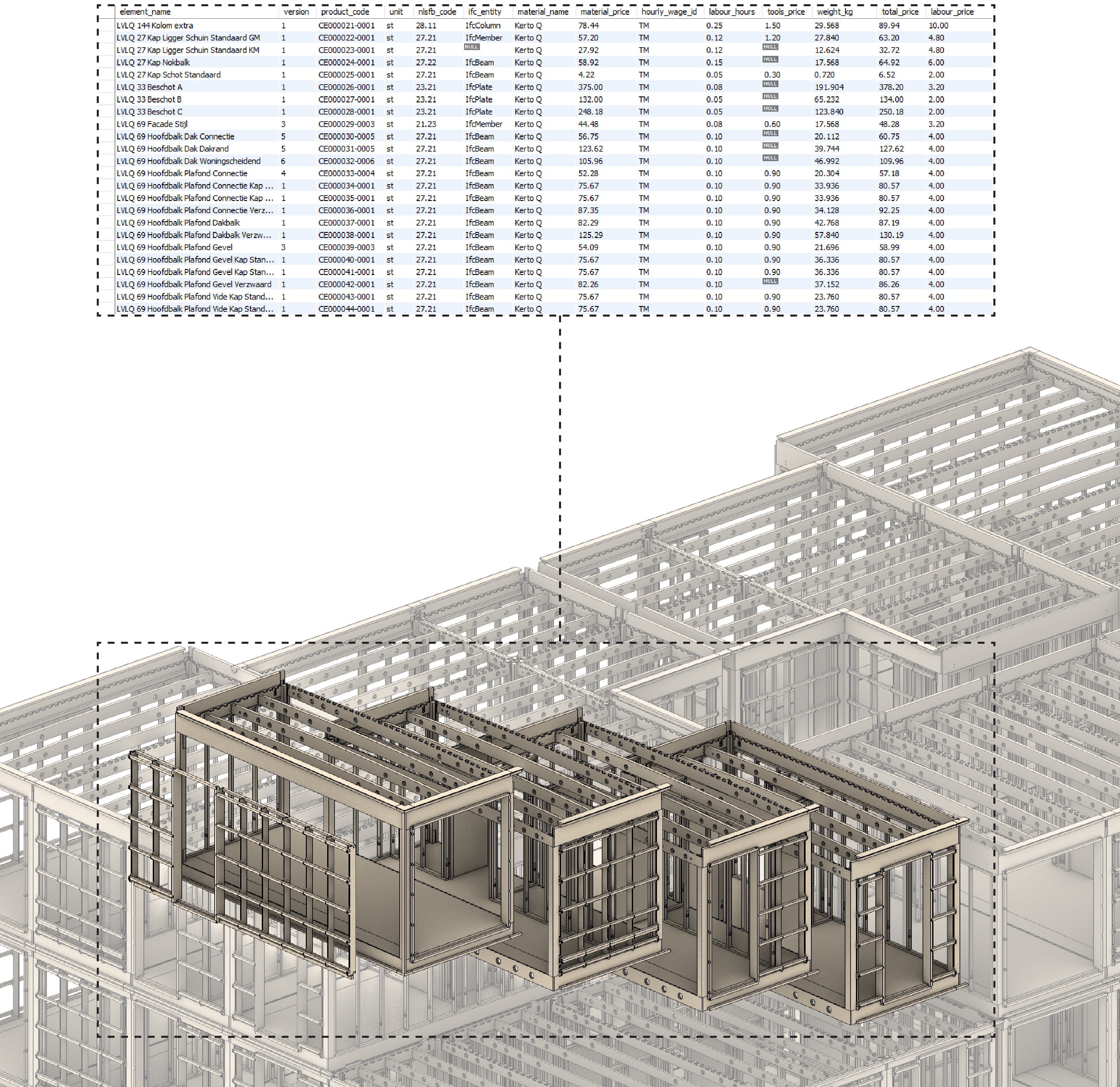

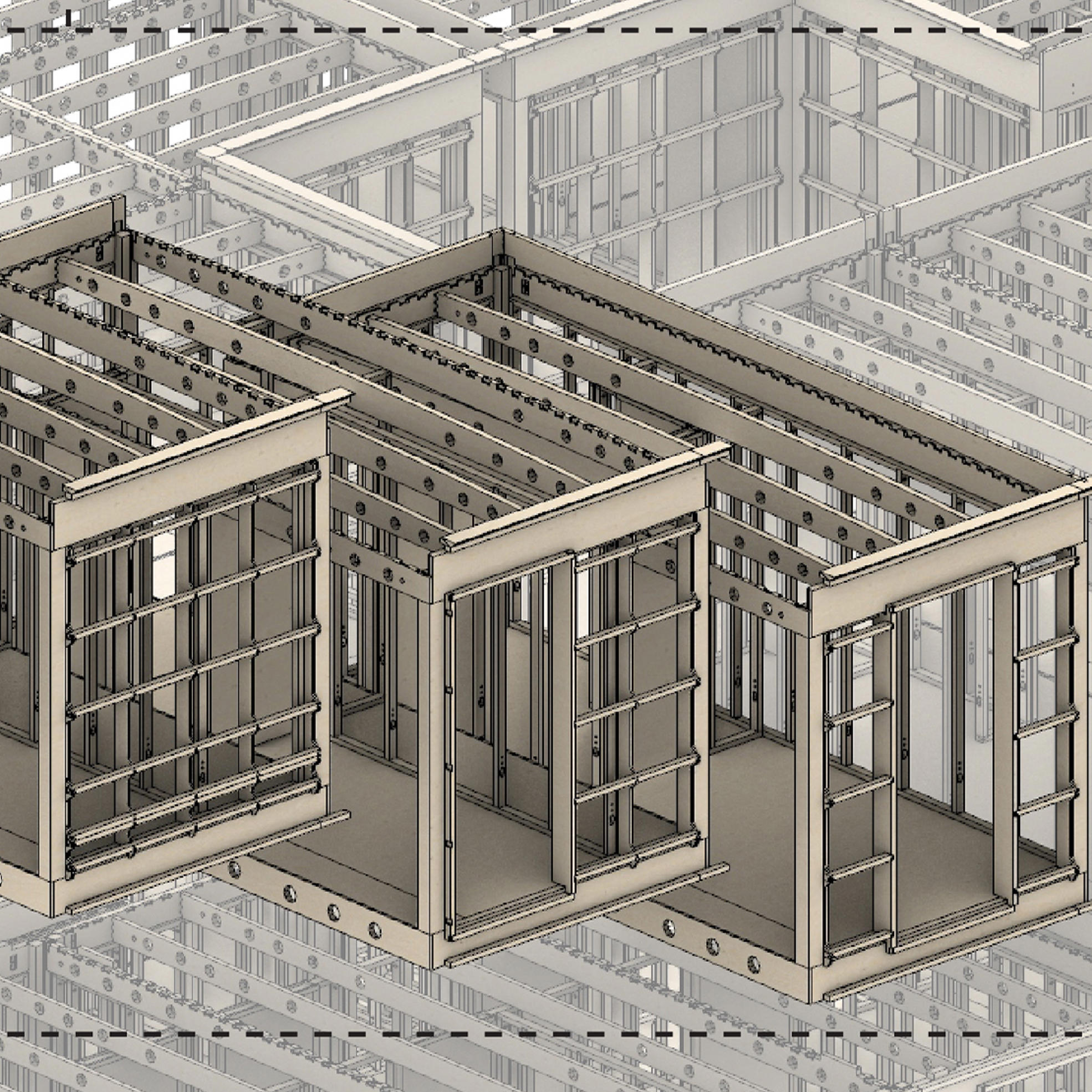

The circularity is supported by a digital passport of all the materials and elements used in the building’s construction. In the design, engineering and production process of buildings, Sustainer’s in-house software creates digital twins, where every element is tracked and linked with a wide range of associated data. Moving from the digital to the physical world, this data can be accessed via a special QR code attached to each element. When scanned, the QR code reveals all the attributes of the element and references back to the detailed model of the entire building.