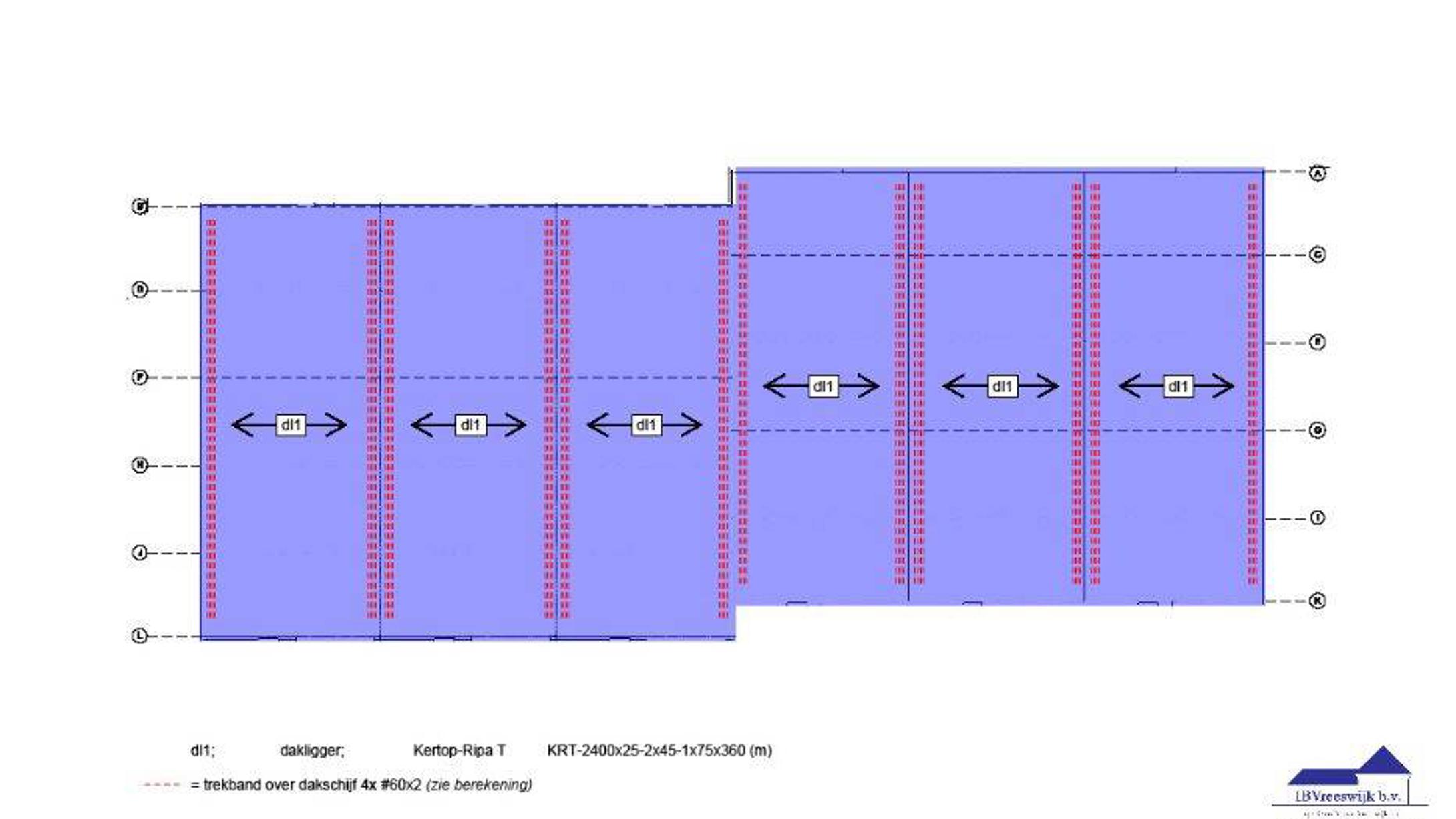

Innovative design with Kerto LVL

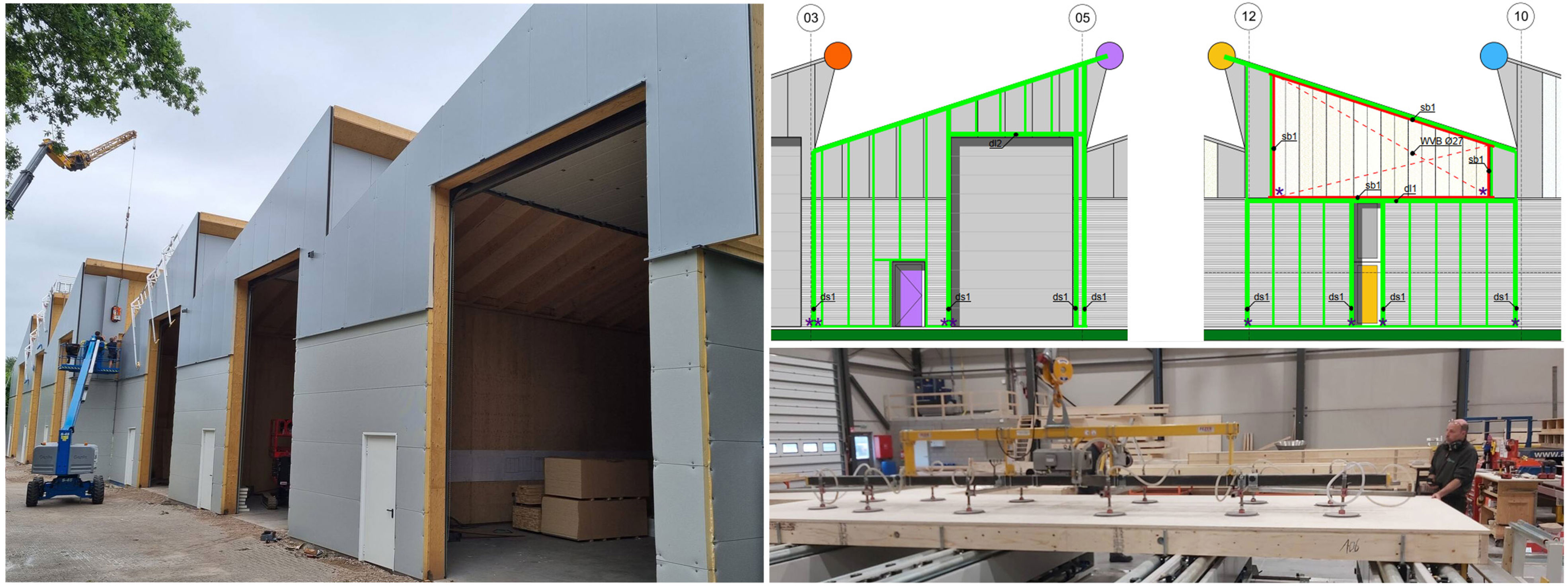

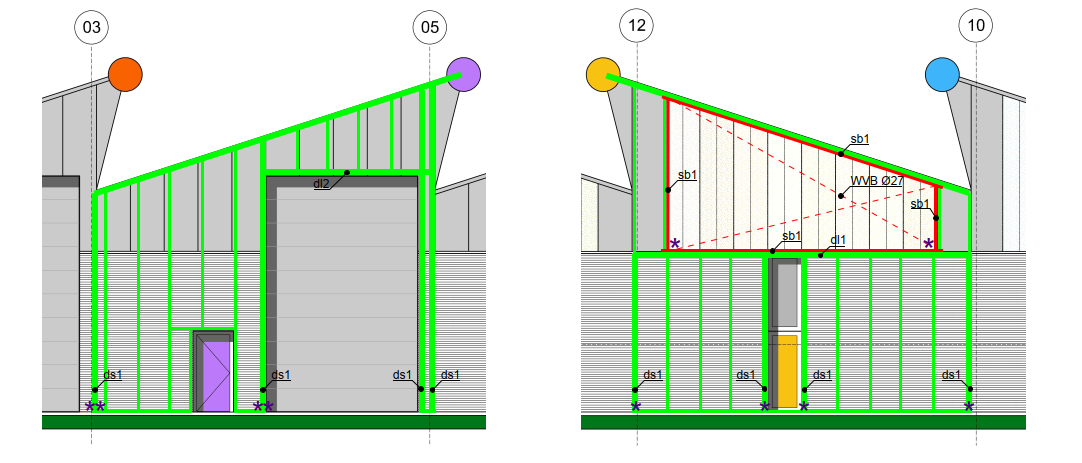

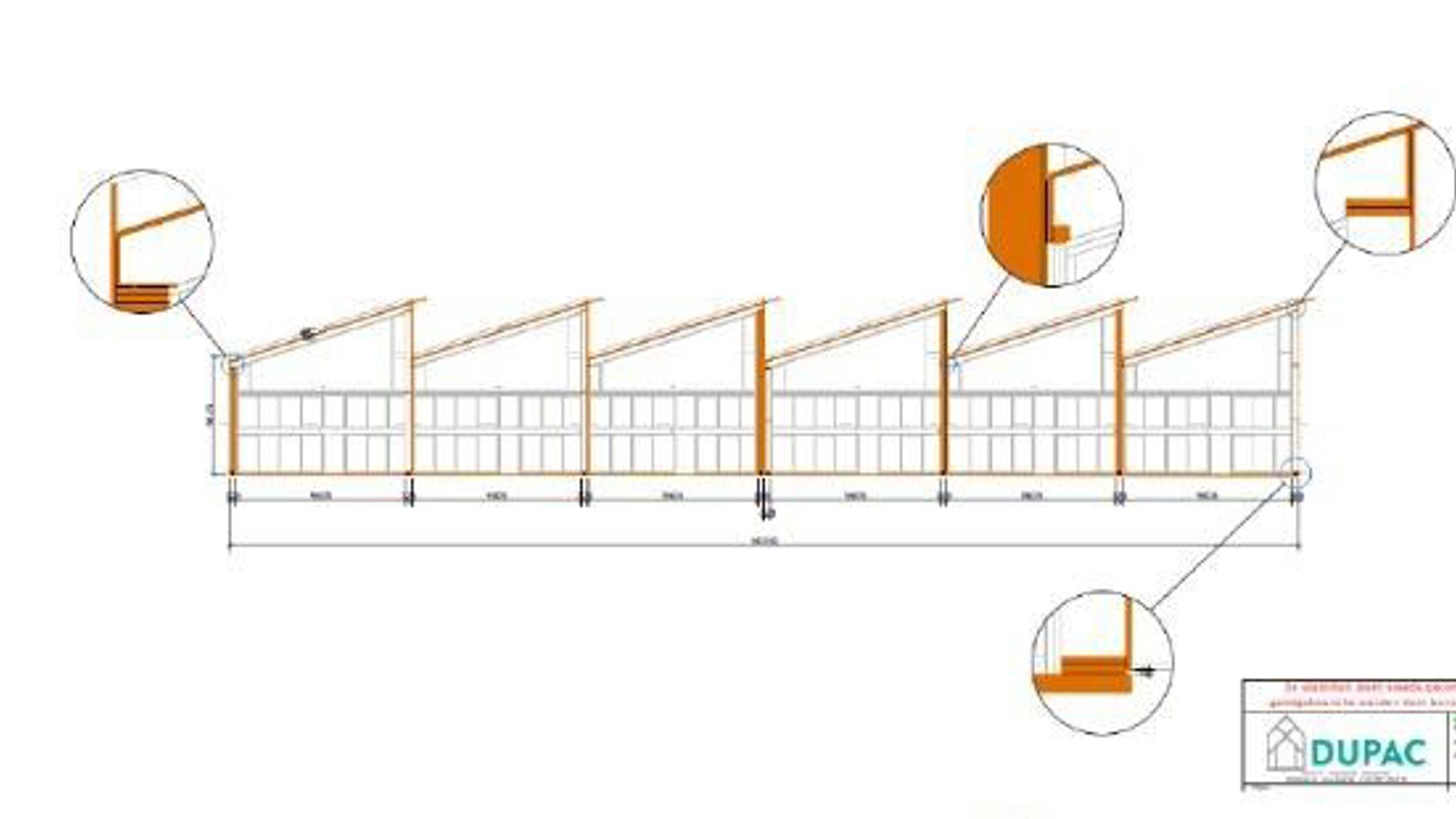

Designer Martin Kloppers from Max 3D was entrusted with the task of designing six halls, each with dimensions of 25x10m, totalling 1500m2. The six mono-pitched roofs, each standing at 10 meters in height and length, offer plenty of space for the construction of large carnival floats and allow abundant natural light to flood in, maintaining the structure's natural essence.

By collaborating with structural engineer Bas Vreeswijk, they brought on board an engineer with a profound passion for wood and extensive experience working with Laminated Veneer Lumber (LVL). Metsä Wood’s Kerto LVL was used for the entire structure, encompassing the roofs, walls, and floors.