Major construction projects are traditionally implemented on-site, regardless of the conditions and amount of natural light. Consequently, the possibilities of efficient, high-quality construction decrease with more difficult weather conditions and reduced light. Lehto Group has addressed this development need.

Lehto Group is a Finnish company specialising in economically driven construction. It aims to replace prototype construction – that is, the individual construction of each building on-site – with industrial production, which is more cost-effective and ensures higher quality. Homes will increasingly be built in factories, where it is easier to control the quality and costs of production.

Using wood in off-site construction

Metsä Wood also supports the transition to industrial prefabrication, or off-site construction. “Urbanisation and climate change are global megatrends that necessitate the development of more sustainable solutions in response to the continuously increasing demand for homes,” says Virva Juhola SVP sales and marketing at Metsä Wood.

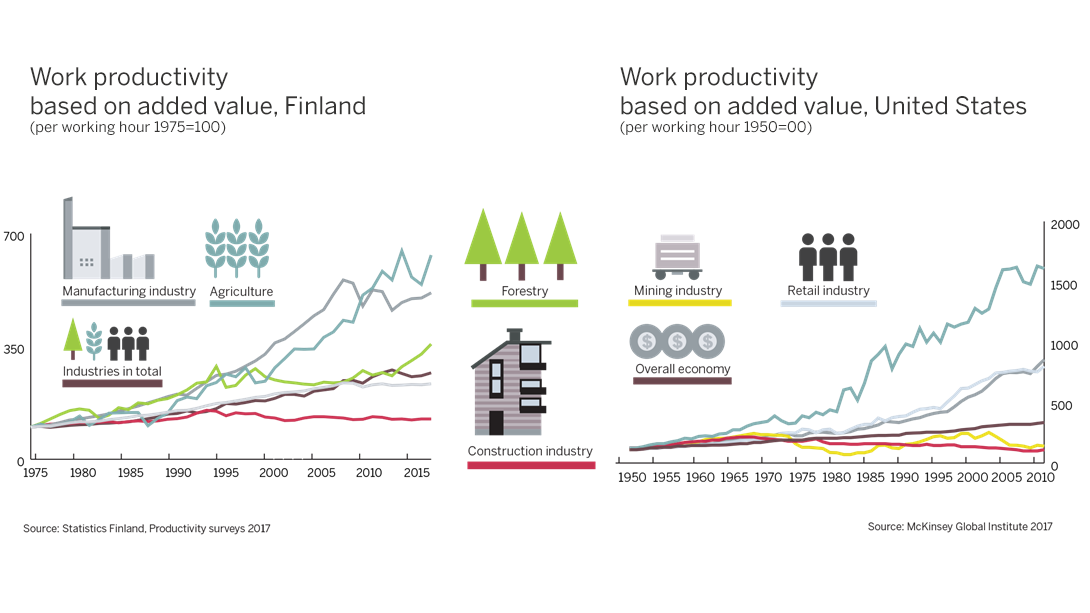

“In this transition, industrial prefabrication and scalable concepts lead the way for new ways of doing things better in the construction industry, which is lagging significantly behind other sectors in productivity development.”