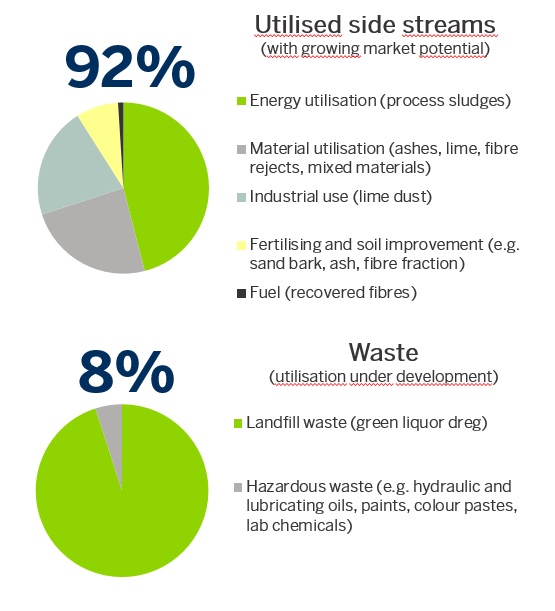

The optimal and wise use of resources is not a new thing. Forest industry processes have been resource-efficient for a long time, but circular economy is taking the wise use of resources to a new level. The circular economy seeks to preserve the value of used materials as high as possible for as long as possible. In other words, the idea is to avoid waste and use fractions previously classified as waste as raw materials for other products. This is best achieved in industrial ecosystems and cooperation networks including companies that manufacture a diverse range of products. Metsä Group has been developing the utilisation of production side streams for years, and the share of utilised side streams was as high as 92 per cent in 2017. Side streams represent around 5 per cent of Metsä Group’s total production.

Utilising side streams calls for inventiveness and open cooperation

Developing circular models and identifying new uses for fractions previously classified as waste, i.e. by-products, calls for continuous development and a wide, cross-industrial perspective. For this reason, development projects bringing together various companies and research institutes are extremely important and beneficial.

“New applications for side streams often arise from a partner’s desire to replace virgin raw materials or a joint desire to promote the circular economy. It’s important to keep your eyes open and be proactive in partner networks. As a major industrial operator, we offer useful side streams, and the development of their upgrading is important for us,” says Development Manager Sanna Pulkkinen, who is in charge of developing new ways to use Metsä Group’s side streams.

Metsä Group’s production generates a diverse range of side streams. Location of the mill site and the properties of the side stream usually determines which types of partnerships and utilisation models gives the best circularity and economy.

“When creating partnerships, you always have to pay attention to the big picture. Many factors determine what type of utilisation is reasonable. For example, it’s not economical to transport fractions over long distances. Instead, you need to find a partner nearby. Due to the wide range of factors, such as the location of the production facility and the amount and properties of the fractions, this work can be challenging, and it sometimes requires quite a lot of imagination,” Sanna explains.

From side streams to soil improvement materials and concrete

Metsä Group participates in many carefully selected cooperation projects, such as the Urban Infra Revolution project coordinated by the City of Lappeenranta and Lappeenranta University of Technology. The project is studying the possibility of making use of ash and green liquor sludge in construction materials suitable for 3D printing. The Sustainable Bioresidual Concrete (Kestävä bioresiduaalibetoni) project of Jyväskylä University of Applied Sciences is also studying the partial replacement of cement in concrete with green liquor sludge and ash.

In addition, fertilisers and soil improvement materials are an important application for forest industry’s side streams. Metsä Group participated in the NSP Pulp project which studied the fertilising and soil-enriching impacts resulting from using wood fibres. This project started in 2014. In soil improvement, wood fibre has been proven to decrease the risk of nutrients leaching from the fields into watercourses. Wood fibres also bind carbon originating from the atmosphere, which slows climate change. The NSP Pulp project is continuing with a two-year Nutrient Fibre (Ravinnekuitu) project, which is studying the agricultural use of fibre-rich side streams from the forest industry.

“It’s great to be able to participate in interesting and innovative cooperation projects, because combined knowledge always creates a broader perspective,” says Sanna.